PLAZROK AGGREGATE

Would you prefer a lightweight concrete on your next project?

An Advanced Product of the Future

Plazrok™ is manufactured specifically to be a lightweight composite aggregate, made entirely from the waste stream, designed as an additive or a replacement for conventional aggregates for a variety of concrete applications. Plazrok™ not only provides a variety of advantages to concrete but uses all plastic waste without the necessity to sort or separate along side a variety of other waste derived from landfills.

Tomorrow’s Lightweight Concrete – Today

Concrete made with Plazrok™;

- Can be manufactured between 10 – 40% lighter than concrete made with traditional stone aggregate.

- Achieves compressive strengths like conventional concrete.

- Has potential seismic advantages, because it is in a position to compress and flex without breaking or cracking to a greater degree than concrete made with traditional stone aggregate.

The logistics of transporting and construction are reduced, because the weight of Plazrok™ is ¼ of traditional stone aggregate, resulting in a discount in transport costs to the development site, labour and construction time when used.

Repurposing At Its Best

Concrete made with Plazrok™ aggregate has the environmental benefits of reducing landfill and fixing carbon from the ecosystem. Plazrok™ is undoubtably a technically viable socially acceptable future solution to the waste plastic disposal problem which will be released globally and profitably with benefits for both the environments and concrete industries

Plastic is one among the foremost useful and important materials in modern society, however, concern about the environmental impacts of plastic on the world’s ecosystems are growing.

The facts;

- 320 million tonnes of plastic are produced globally annually

- 280 million tonnes of plastic finishes up in landfill

- 20 million tonnes of plastic finishes up within the world’s oceans

- The balance is recycled, remains in use or unreported

- Global Demand for Construction Aggregates to Exceed 48 Billion Metric Tons in 2016

Answers To The Most Common Questions

Can Plazrok be recycled and reused?

Yes, as Plazrok acts within the same way as conventional (basalt) aggregate in concrete, it can and is often recycled. The technology round the manufacture of Plazrok and its specific properties make it ideal for recycling. Actually, it’s capable of being recycled more than once.

Is Plazrok suitable to be used in house construction or road works?

Concrete incorporating Plazrok is often utilised in any application where concrete with conventional aggregate is employed. However, in building construction where a substantial reduction in overall weight, and Plazrok’s ability to attain green strength sooner than conventional concrete offers significant advantages to users.

In terms of housing construction “tilt up slabs” using Plazrok aggregate have shown substantially superior results in all tests in terms of weight and therefore offering a much-improved turnaround of moulds used to form the slabs. The results of which meaning potentially faster erection and building times and lower overall costs.

In respect of roading – Concrete incorporating Plazrok aggregate exhibits superior flexural strength which translates into a capability to absorb those heavy loads from sudden weights and heavy traffic. While roading isn’t the primary focus of Plazrok at this point, our team in Thailand together with other parties around the world continue with testing programmes for a wide range of potential uses for Plazrok for any manner or size of construction and usage.

Does Enviroplaz International recycle used tyres?

No. Rubber is not a product that can be formed with sufficient strength to be incorporated in concrete products.

What can’t we use in Plazrok ?

In terms of current plastic waste streams, Plazrok takes a totally co-mingled waste plastic stream from grades 1-7. This includes all plastic bags, multi laminate food packs incorporating aluminium foil (chip packets), all plastic wrapping from glad wrap to agricultural wrapping, packaging strapping and polystyrene cups, plates, boxes and generally all forms of plastic packaging. So in effect, virtually all sorts of waste plastic. Additionally Plazrok uses coloured glass (that can’t be recycled) and fly ash which is a by-product of cement manufacture.

What would be the results of concrete using Plazrok aggregate if heated by the sun?

Heating concrete incorporating Plazrok will not have any detrimental effects because it is completely encapsulated within the concrete matrix. In terms of being exposed to a fire scenario, Plazrok doesn’t absorb moisture like a conventional aggregate would and can not cause a structural breakdown (Note: conventional aggregate during a fire situation can cause structural breakdown from heated steam). Plazrok is now undergoing a variety of fire related tests to verify current findings.

Will Plazrok be subject to decomposition that would release toxic gasses into the encompassing environment?

No, Plazrok is extremely inert, it doesn’t give off any toxic gasses. Plazrok doesn’t absorb moisture and there’s nothing to encourage leaching of any chemicals from within the specific product. As with the heat and fire testing, Enviroplaz International is now undergoing further independent testing in Singapore to investigate all forms of exposure and possible degradation to further verify the present findings.

New Technology Concrete Mix

Plazrok incorporated ready-mix concrete can be used in a wide range of application currently using conventional ready-mix concrete.

Plazrok incorporated concrete can be produced up to 40% lighter and trial batch have been done with total coarse aggregate replacement. This lightweight aspect has enormous cost saving potential with the increase in payload and the reduction of gross weight.

Compressive strengths of up to 45mpa can and have been achieved.

Tensile strengths 3 times that of normal concrete can be achieve with the addition of Plazrok.

Early onset of green strength can be helpful when using Plazrok incorporated ready-mix concrete in moulding applications.

Plazrok incorporated ready-mix concretes can help improve R values and provide better thermal and acoustic performance.

Use of Plazrok in ready-mix concretes provides opportunities for LEED, EDGE, TREES, GREEN MARK and other sustainable solution ratings.

Lightweight Concrete Panels

Plazrok incorporated concrete can be used for the production of lighter weight tilt up panels used anywhere from walls to facades to noise barriers.

Early onset of green strength can be achieved when using Plazrok incorporated concrete in moulding applications.

An 1800kg/m3 Plazrok incorporated concrete can achieve a (1) day compressive strength of 11Mpa with a flexural strength of 2.5Mpa. At (7) days it achieves a compressive strength of 22Mpa and 4.00Mpa flexural strength.

Plazrok incorporated concrete can be produced up to 40% lighter This lightweight aspect has enormous cost saving potential with the increase in payload and the reduction of gross weight.

Compressive strengths of up to 45mpa can and have been achieved.

Tensile strengths 3 times that of normal concrete can be achieve with the addition of Plazrok.

Plazrok incorporated concretes can help improve R values and provide better thermal and acoustic performance for walls and noise barriers

Use of Plazrok incorporated concretes provides opportunities for LEED, EDGE, TREES, GREEN MARK and other sustainable solution ratings.

Lightweight Concrete Floor Toppings

Plazrok incorporated concrete can be used for the production of floor topping and can be pumped using conventional concrete pumps in the same way as standard ready-mix concrete.

Early onset of green strength can be achieved when using Plazrok incorporated concrete and can speed up production.

Plazrok incorporated concrete can be produced up to 40% lighter. This lightweight aspect has enormous potential to reduce the load on a multi-story building along with cost saving made in transportation of the concrete to site with the increase in payload and the reduction of gross weight.

Compressive strengths of up to 45mpa can and have been achieved.

Tensile strengths 3 times that of normal concrete can be achieve with the addition of Plazrok.

Plazrok incorporated concretes can help improve R values and provide better thermal and acoustic properties which in turn can help with the performance of the floor topping.

Use of Plazrok in Plazrok incorporated concrete provides opportunities for LEED, EDGE, TREES, GREEN MARK and other sustainable solution ratings.

Lightweight Concrete Dry Mix

Plazrok incorporated dry-mix bagged concrete can be used in a wide range of application currently using conventional bagged concrete mixes.

Plazrok incorporated dry-mix bagged concrete can be produced up to 40% lighter This means getting more volume for weight in a bag.

With a 40% reduction in weight, you can increase the volume of your bag by 40% and still be at the recommended weight level. This is greater value to your customer.

The use of waste plastic and the recycling aspect of Plazrok will appeal to your customer base in the DIY market.

Use of Plazrok in ready-mix concretes provides opportunities for LEED, EDGE, TREES, GREEN MARK and other sustainable solution ratings.

Media

Since our commencement of the Plazrok development we have attracted media attention both for the innovative concept of lightweight concrete but perhaps even more so because of the massive amount of recycling involved to produce a product that is in such high demand.

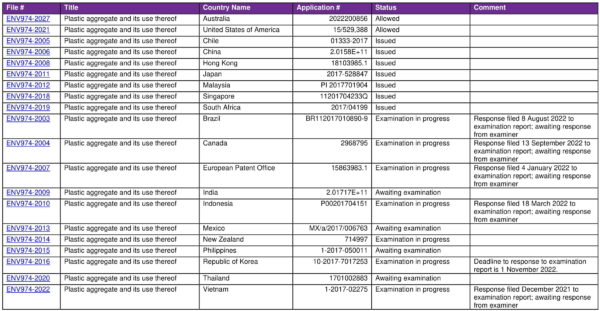

Plazrok Patents – Status as at October 2022

Plazrok are pleased provide an update on the current status of our international Patents to ensure protection of our product and secure the future success of same. We invite you to click this link to view the details. https://plazrok.com/the-product/?url=Patents/